Purchasing a piece of fire apparatus is an extremely complex undertaking. Not only are department officials responsible for spending the taxpayer’s money wisely, but they also want to be confident that the apparatus they buy is designed and engineered for its intended mission. It should be built with heavy-duty components and assembled with careful and exacting craftsmanship. Unfortunately, in the apparatus market, there are many manufacturers who insist on compromises. They want you to take what they build and make it work rather than building a truck designed for your specific needs. They focus strictly on price rather than function.

Purchasing a piece of fire apparatus is an extremely complex undertaking. Not only are department officials responsible for spending the taxpayer’s money wisely, but they also want to be confident that the apparatus they buy is designed and engineered for its intended mission. It should be built with heavy-duty components and assembled with careful and exacting craftsmanship. Unfortunately, in the apparatus market, there are many manufacturers who insist on compromises. They want you to take what they build and make it work rather than building a truck designed for your specific needs. They focus strictly on price rather than function.

The following pages will illustrate the features and benefits of Toyne as the right choice for your next apparatus. Highlights of these include:

- Company Background

- Product Line-up

- Body Construction Features

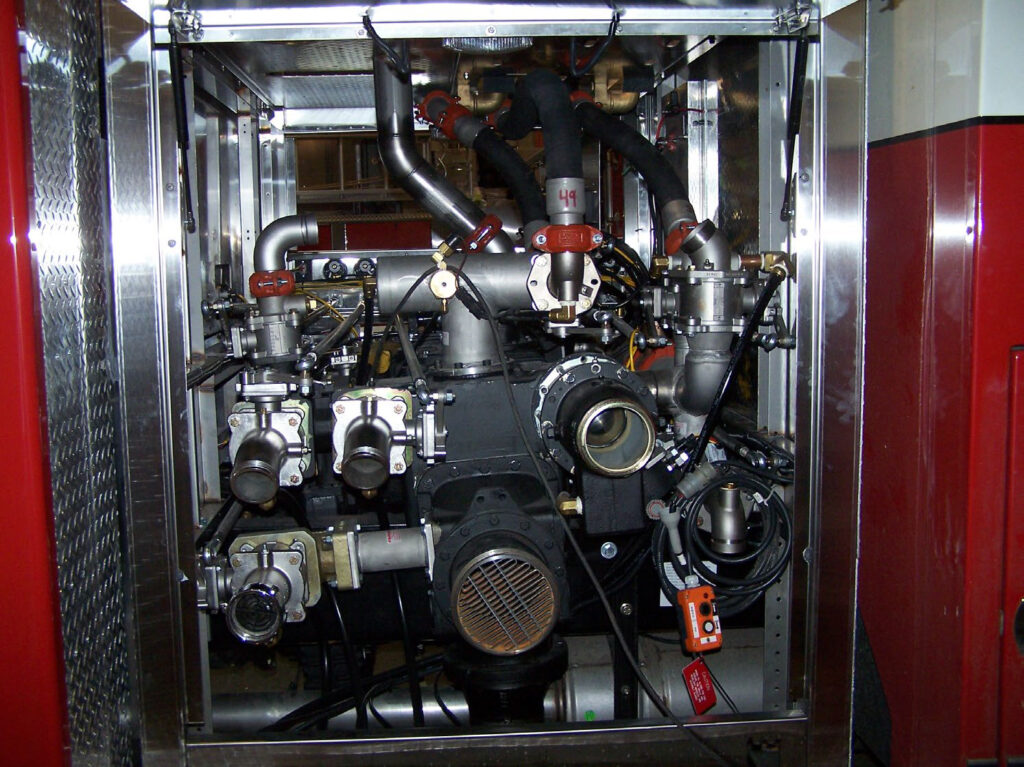

- Pump and Plumbing

- Electrical System

Toyne, Inc., is a family owned, American owned company that has been building fire apparatus bodies since 1942 to meet the demanding needs of the fire service. There are many reasons why Toyne is selected as the overwhelming choice of departments wanting to exit from the “cookie cutter” “low dollar” apparatus market. Toyne is recognized as a company with a long and successful record of building “Toyne Tailored” custom-crafted apparatus to meet the needs of the fire service. Toyne builds a high-quality apparatus at an affordable price.

After reviewing this information, we think you will find that while Toyne is not always the least expensive apparatus, it is the best value for your dollar. Low bid is not always best bid. Cost of ownership should be factored into the purchasing decision.

Toyne also offers a 3CR12 utility stainless-steel in a welded body format. The 3CR12 utility stainless-steel is a proprietary product of Columbus Steel and is used by several fire apparatus manufacturers for both apparatus body and cab manufacturing. This steel has a higher carbon content than the 304L (a magnet will stick) but offers great strength and durability as a product and is easy to work. This welded body is fully finish painted. The 3CR12 utility stainless-steel is a great choice for those who want the advantages of welded stainless.

Toyne also offers a 3CR12 utility stainless-steel in a welded body format. The 3CR12 utility stainless-steel is a proprietary product of Columbus Steel and is used by several fire apparatus manufacturers for both apparatus body and cab manufacturing. This steel has a higher carbon content than the 304L (a magnet will stick) but offers great strength and durability as a product and is easy to work. This welded body is fully finish painted. The 3CR12 utility stainless-steel is a great choice for those who want the advantages of welded stainless. Plumbing

Plumbing

Image from Akron/Weldon

Image from Akron/Weldon